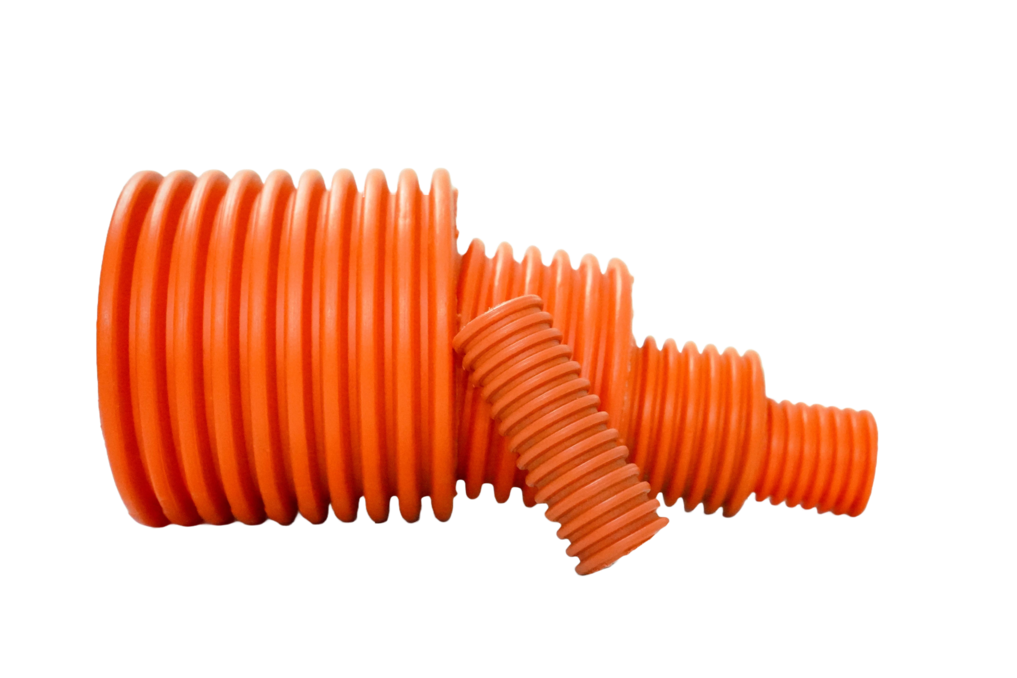

DWC Pipe

SHRI JAGANNATH DWC Pipes are made of High Density Poly Ethylene Polymers.

The DWC pipes shall consist of two layers, the outer layer will be corrugated and the inner layer shall be plain & smooth. These pipes are created by fusing twin layers of High Density Polyethylene, which are corrugated on the outside and have a glass smooth inside.

Testing and Laboratory

Our testing facilities are capable of performing the most stringent tests required for the piping system. These standards cover applications from electrical cable ducting to underground waste water transportation networks and piping systems.

Our advanced infrastructure and focus allows us to maintain a superior product quality which can be constantly monitored and improved over time.

We are equipped to carry out as per IS: 14930 Part II : 2001. This helps us to maintain superior quality and to ensure trouble free performance of our products. Some of the important tests for double wall corrugated pipes are as given below.

- Compression Test

- Impact test

- Bending Test

- Oxidation induction test

- Flame propagation test

- External Influences

- Degree of protection ingress of foreign solid objects

- Degree of protection - Ingress of water

- Anti-Rodent test

Applications

Telecom Application

- Used as the main duct in sub duct network design.

- Protection of ducts and optical fibre cables in city networks.

- Protection of ducts / cables in rail & rail crossings.

- Protection of ducts / cables across rivers disused canals etc.

- Used as casing of copper cables.

Electrical Applications

- In the electrical networks, protective casing of street lighting cables-pole to pole application.

- In the electrical networks, protective casing of street lighting cables-pole to pole application.

Features / Properties

- Resistance to chemical: Exceptional resistance to all internal & external corrosion.

- Will not rust or rot.

- Resistance to electrolytic corrosion.

- Easy to install.

- Longer life than GI, MS & RCC.

- Flexible, can be bent to a radius as low as 10 x OD of the duct.

- Very good thermal insulation due to low thermal conductivity.

- Light weight product for easy transportation, handling and fitting etc.

- Possibility of laying of additional ducts due to aligned joints, continuous length and smooth bends.

- Good mechanical properties and ability to take heavy loads.

- Anti rodent.

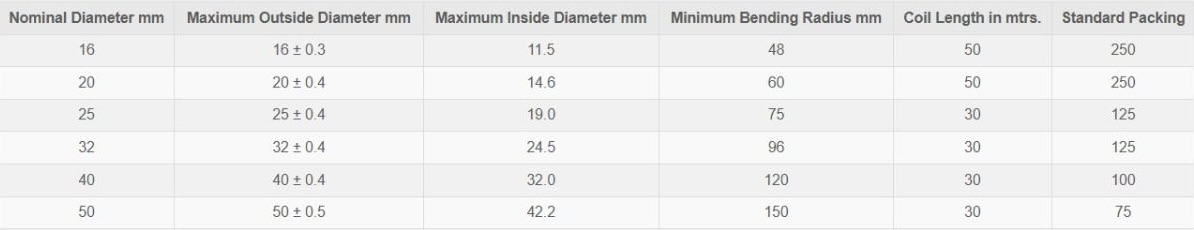

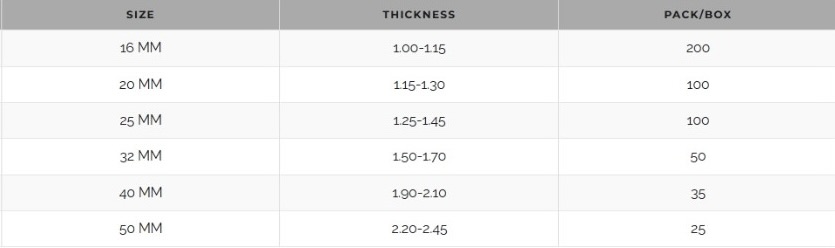

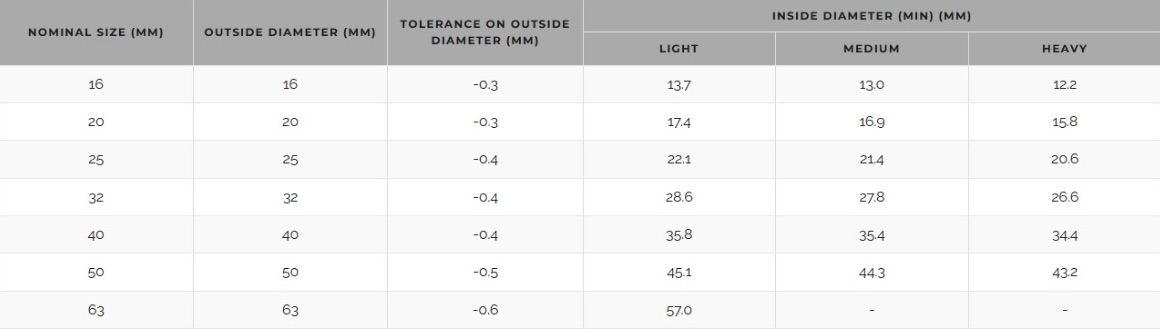

Wide Range of Sizes